Gas Turbine Deposition and Fouling

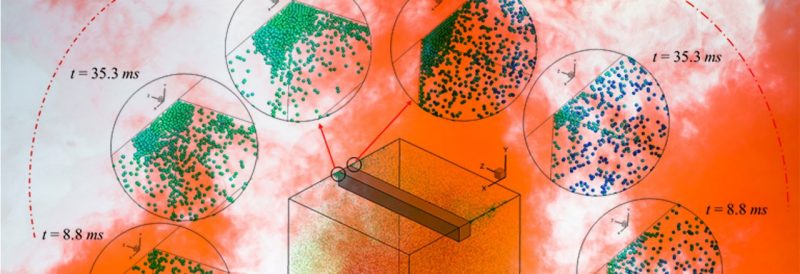

Ingestion of sand, dirt and volcanic ash into a gas turbine engine can cause erosion and deposition in the engine. Deposition can block cooling circuits, can reduce heat transfer, and change the aerodynamic performance of components. The research focuses on the turbulent transport of particulate matter in the flow path and modeling the impact mechanics of particles with the surface.

- Steven Paul (MS 2018)

- Cody Dowd (MS 2016)

- Kuahai Yu (visiting scholar, 2015-16)

- Sukhjinder Singh (PhD 2014)

- Jonathan Cowan (MS 2009)

- Sai Srinivasan (PhD 2010)

Publications

Journal

- Yu, K. and Tafti, D. K. “Size and temperature dependent collision and deposition model for micron-sized sand particles”, Turbomachinery 141(3) 031001, January 2019. https://doi.org/10.1115/1.4042215.

- Yu, K., Elghannay, H.A. and Tafti D.K., “An Impulse Based Model for Spherical Particle Collisions with Sliding and Rolling,” Powder Technology 319, September 2017, pp. 102-116 DOI: https://doi.org/10.1016/j.powtec.2017.06.049

- Yu, K. and Tafti D. K. “Impact model for micrometer-sized sand particles,” Powder Technology 294, June 2016, pp. 11-21. (doi:10.1016/j.powtec.2016.02.014)

- Singh, S. and Tafti, D. K. “Prediction of Sand Transport and Deposition in a Two-Pass Internal Cooling Duct,” ASME J. of For Gas Turbines and Power, July 2016, Vol. 138 (7), 072606:1-12. (doi:10.1115/1.4032340)

- Singh, S. and Tafti, D. K., “Particle deposition model for particulate flows at high temperatures in gas turbine components,” Int. J. Heat Fluid Flow 52, April 2015, pp. 72-83. (http://dx.doi.org/10.1016/j.ijheatfluidflow.2014.11.008).

- Singh, S. and Tafti, D. K., “Sand transport in a two pass internal cooling duct with rib turbulators,” Int. J. Heat and Fluid Flow 46 (2014) 158-167. (doi: 10.1016/j.ijheatfluidflow.2014.01.006)

- Shrinivas, S. S., and Tafti D. K., Effect of blowing ratio on early stage deposition of Syngas ash on a film cooled vane leading edge using large eddy simulations, ASME J. Turbomachinery 135(6),061005, Sep. 13, 2013. (doi: 10.1115/1.4025153)

- Shrinivas, S. S. and Tafti, D. K., Composition dependent model for the prediction of syngas ash deposition in turbine gas hotpath, Int. J. Heat Fluid Flow 32, pp. 201-211, 2011.

- Rozati, A., Tafti, D. K. and Sreedharan, S. S., Effect of Syngas Particle size on Deposition and Erosion of a Film Cooled Leading Edge, ASME J. Turbomachinery, 133(1), 011010, Jan. 2011

- Shah, A. and Tafti D. K., Transport of Particulates in an Internal Cooling Ribbed Duct, ASME J. Turbomachinery, 129(4), 816-825, October 2007.

Conference

- Paul, S., Tafti, D. K. and Yu K., “A Computational Framework for Deposit Formation and Growth,” Paper No. GT2019-90266, Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference & Exposition, June 17-21, 2019, Phoenix, Arizona, USA.

- Dowd, C., Tafti D.K. and Yu, K. “Sand Transport and Deposition in Rotating Two-passed Ribbed Duct with Coriolis and Centrifugal Buoyancy Forces at Re=100,000,” Paper no. GT2017-63167, Proceedings of ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition GT2017, June 26-30, 2017, Charlotte, NC, USA.

- Yu, K. and Tafti D.K. “Size and Temperature Dependent Deposition Model of Micro-sized Sand Particles,” Paper no. GT2017-63792, Proceedings of ASME Turbo Expo 2017: Turbomachinery Technical Conference and Exposition GT2017, June 26-30, 2017, Charlotte, NC, USA.

- Singh, S. and Tafti, D. K., “Prediction of Sand deposition in a Two-Pass Internal Cooling Duct,” Proceedings of ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, GT2015-44103, June 15-19, 2015, Montreal, Canada.

- Singh, S. and Tafti D. K., Predicting the coefficient of restitution for particle wall collisions in gas turbine components, Paper No. GT2013-095623, Proceedings of the ASME Turbo Expo 2013, June 3-7, 2013, San Antonio, Texas, USA.

- Singh, S., Reagle, C., Delimont, J., Tafti, D. K., Ng, W. and Ekkad, S., Sand Transport in a Two Pass Internal Cooling Duct with Rib Turbulators, ASME Summer Heat Transfer Conference, Puerto Rico, July 8-12, 2012.

- Sreedharan, S. S., Tafti, D. K., Composition Dependent Model for the Prediction of Syngas Ash Deposition With Application to a Leading Edge Turbine Vane, Proceedings of the ASME Turbo Expo 2010, Paper No.: GT2010-23655, June 14-18, Glasgow, UK.

- Sreedharan, S.S., and Tafti, D.K., Effect of blowing ratio on syngas flyash particle deposition on a three-row leading edge film cooling geometry using large eddy simulations. Proceedings of ASME Turbo Expo 2009, June. 8-12, Orlando, Florida. ASME Paper No. GT2009-59326.

- Rozati, A., Tafti, D. K., Shreedharan, S., Effects of Syngas Ash Particle size on Deposition and Erosion of a Film-Cooled Leading Edge, Paper No. 56155, 2008 ASME Summer Heat Transfer Conference, Aug. 10-14, Jacksonville, Florida.

- Shah, D. K. Tafti, Transport of Particulates in a Rotating Internal Cooling Duct, FEDSM2006-98020, ASME Joint US-European Fluids Engineering Summer Meeting, July 17-20, 2006, Miami, Florida, USA.

- Shah, A. and Tafti D. K., Transport of Particulates in an Internal Cooling Ribbed Duct, GT 2006-91284, ASME Turbo Expo 2006, 8- 11 May 2006, Barcelona, Spain.